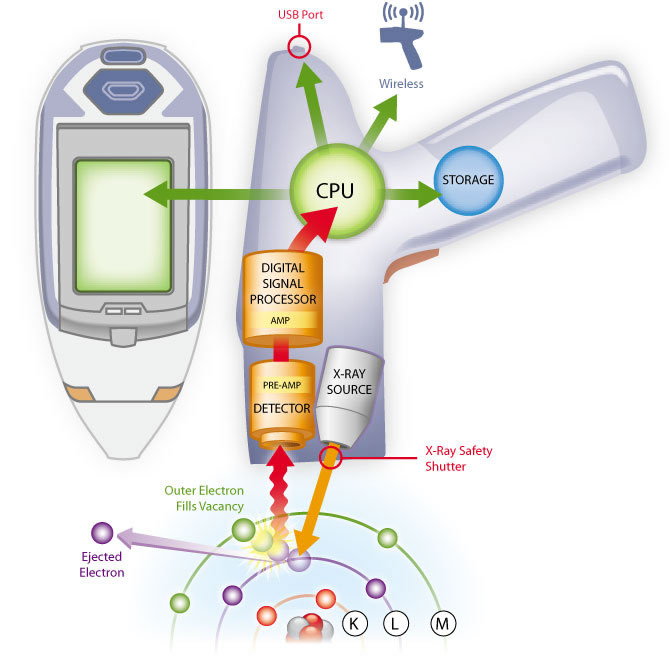

X-ray fluorescence (XRF) is an analytical method using emission spectroscopy to identify the presence of specific elements in most materials. Every element has a unique emission signature, making it possible to quantify the presence of an element by the relative strength of the emission. Instrumentation has evolved to the point where hand-held XRF can be used in the field for on-site testing purposes. While X-ray fluorescence is a very accurate and reliable instrumentation-based method for quantitative analysis of chemical elements, it should not be used as the sole identifier of toxic or Chinese drywall. To identify problem drywall, XRF is used to target the alkali earth element, strontium, as the primary identifier of problem drywall. There is no doubt the XRF will determine the accurate level of strontium in the wall section being scanned. However, there are several chemistry-related considerations that should force us to take a closer look at using only strontium content as the flag for identification of problem drywall.

What is Strontium?

Strontium is a relatively plentiful element on Earth. Strontium-containing minerals, such as strontianite (strontium carbonate) and celestite (strontium sulfate), may be found in various concentrations in natural gypsum deposits. Natural gypsum is used in the production of drywall. Therefore, drywall will often have some strontium present at varying levels.

Strontium is commonly used in paints and coatings for a variety of purposes. Here are a few examples:

- Strontium frequently replaces lead as a paint drier.

- Strontium is used in yellow, blue, red and white pigments.

- Strontium aluminate is used in glow-in-the-dark coatings, wallpapers and adhesive stickers.

- Strontium chromate, borate and metaborate are also used in anti-corrosion additives, flame retardants, and anti-microbial agents in paints and coatings. Therefore, it is conceivable that XRF readings for strontium could vary from room to room and even from wall to wall due to differing layers of paint.

Is Strontium to Blame?

The EPA, the University of Florida, and other entities have published reports suggesting that strontium sulfide is a possible source of the corrosive sulfur gasses emanating from problem drywall. The difficulty with this scenario is that the chemical reactions do not work neatly using strontium sulfide as the source of corrosive and toxic gasses. Strontium sulfide is a stable compound that is insoluble in water. The generation of hydrogen sulfide gas from strontium sulfide requires reaction with an acid. Since drywall maintains a neutral-to-alkaline pH, it is difficult to calculate how the acid reaction will occur with the mere presence of humidity in the air.

Additionally, testing results from hundreds of known problem drywall specimens accumulated by the Exterior Design Institute report that problem drywall is typically ten times more alkaline than non-problem drywall. The alkaline pH makes the generation of hydrogen sulfide gas from strontium sulfide even less likely. There is more empirical data that indicates that strontium sulfide is not the source of the corrosive gasses. The additional data lies in the fact that a known percentage of drywall specimens with high levels of strontium do not produce corrosive gasses. Further proof lies in the number of drywall specimens with low strontium levels, which do produce corrosive gasses, according to the Building Envelope Science Institute (BESI).

What this means is that strontium is probably not present in the chemical that is producing the corrosive gasses. Although high strontium levels have been found in a majority of problem drywall, by itself, strontium cannot be a 100%-conclusive indicator of problem drywall. The strontium is more likely a marker or “ride-along” component in most problem drywall. In the earlier days of identifying problem drywall, there was a test for elemental sulfur because it was believed to be the cause of the corrosive gasses. We have since discovered that, although elemental sulfur is present in many problem drywall samples, it is not the cause of the gasses. As a result, the presence of elemental sulfur was determined not to be a 100%-reliable indicator of problem drywall. The same appears to be true of strontium.

Summary

The XRF method tests for strontium, which:

- is naturally present in the drywall core;

- is commonly present in wall paints; and

- is NOT the proven source of the corrosive gasses.

To use the XRF method as a stand-alone tool to positively identify problem drywall makes no more sense than to use an X-ray machine as a stand-alone instrument to diagnose cancer. There is no basis in science or experience to support its use as a stand-alone method. There is a basis in science and experience to support the use of XRF as a highly reliable screening method for identifying suspect or problem drywall.

Conclusion

While the XRF method is both fast and non-destructive, it should only be used in concert with complementary problem drywall-testing protocols and trained visual inspection. It is clear that the real benefit of the XRF method is as a very efficient and highly reliable, non-destructive screening tool.

*****************************************************

Nick Gromicko is founder of the International Association of Certified Home Inspectors and the executive director of the International Association of Certified Indoor Air Consultants.

Dennis L. Rose is an industrial chemist and president of D. L. Rose and Associates, LLC, in Ocala, Florida.